by Webmaster | Mar 24, 2014 | News

Rabine Group Employees Shave Their Heads for Charity

Rabine Group Foundation is hosting a St. Baldrick’s Foundation event on April 29th, 2014 at the Rabine Group headquarters in Schaumburg, Illinois.

175,000 children are diagnosed with cancer each year. St. Baldrick’s is a charity which holds head-shaving events with the goal of raising money to fund research to help find cures for childhood cancer. St. Baldrick’s is dedicated to research, prevention, and early detection of childhood cancer.

Rabine Group employees have participated participated in past St. Baldrick’s events, shaving their heads in the name of charity. The Rabine Group Foundation is proud to continue supporting such an amazing cause.

To sign up to shave your head or to donate to the cause, visit www.stbaldricks.org/events/rabinegroupfoundation.

by Webmaster | Mar 12, 2014 | News

The snow is finally melting, revealing thousands of potholes left behind by the worst winter we’ve seen in years.

The Chicago Department of Transportation (CDOT) announced that as of March 2014, over 240,000 potholes have already been filled, with at least 25,000 potholes still tormenting drivers and pedestrians alike.

CDOT filled 625,000 potholes across Chicago in 2013, and it looks like they’ll have their work cut out for them this year. CDOT currently has 36 crews working to finish filling the currently reported potholes.

Potholes damage cars, present trip hazards and cause further deterioration to your pavement. For the safety of your patrons and to extend the life of your lot, it is vital to fill potholes and seal cracks immediately to prevent further pavement damage and to keep moisture out of the pavement. For more information on how you can extend the life of your pavement, contact us at (888) 722-4633.

by Webmaster | Mar 6, 2014 | News

Concrete’s Rock Solid Prices are Winning the Battle for Millions of Square Feet in Parking Lots.

By: Gary Rabine

Asphalt prices increased by 400% between 2006 and 2009 and have continued to rise since. Asphalt prices will continue to rise because the material is dependent on oil. Asphalt requires annual maintenance and has a relatively short life span—usually about 12-16 years assuming the lot is maintained each year.

Commercial property managers and building owners have known that asphalt prices rise and that asphalt parking lots require maintenance for years. So why have asphalt parking lots dominated the capital paving projects for so long?

The first reason is data. As more data about the true cost of maintaining an asphalt parking lot has become available over the last ten years, property managers and building owners are becoming more sophisticated in the way they evaluate capital spend and it’s impact on the ensuing maintenance of the lot. Second, the construction industry has made critical improvements to the equipment used in the placement of concrete. Finally, The Rabine Group invented UltraLot® Whitetopping giving property managers and building owners the option to convert an asphalt lot to a concrete lot at a lower cost than a full concrete replacement.

Pavement companies with national scale are relatively new and organizations like the Rabine Group have dramatically improved the industry’s ability to use data to forecast price increases and measure the cost of maintenance for asphalt lots. The standard methods of crack sealing, seal coating, striping, patching (removal and replacement), and asphalt overlays (resurfacing) will extend the life of an asphalt lot for an additional 5-10 years. However, these maintenance methods are subject to the same price increases as the initial asphalt parking lot! To make matters worse, the equipment required to maintain the asphalt consumes large amounts of oil and gas making the process even more sensitive to persistent oil price inflation. If any money is saved during the initial installation of an asphalt lot, those savings are undoubtedly lost during the maintenance phase of the asphalt parking lot’s life.

Unlike the oil dependent asphalt, the price of concrete placement has fallen due to advances in technology and the construction process. Concrete material by volume is less expensive than asphalt, but until recently, the process of pouring concrete has been much more costly. Equipment used to place asphalt has made dramatic improvements in accuracy, efficiency and accessibility—not to mention the implicit cost savings that a parking lot that lasts more than 40 years delivers to the bottom line. Concrete, on it’s own, has become more price competitive, sustainable and easier to work with while maintaining it’s integrity as a material that will last more than four decades.

It wasn’t until recently that concrete started replacing asphalt overlays in parking lots around the country. The catalyst for this shift is Rabine’s UltraLot® Whitetopping.

The UltraLot® Whitetopping process is similar to an asphalt overlay. The existing asphalt or concrete pavement must be ground down (milled) to the minimum thickness of the overlay application at all the areas of transition between existing asphalt and concrete pavements as well as drainage critical locations. The remaining existing pavement is ground to a minimum thickness, typically 1⁄4-inches to create a rough grooved surface for the concrete to bond when placed. If existing curb and gutter is not present, the perimeter edges must be framed and supported to define the limits of the whitetopping application. At this point, the parking lot is properly prepared and ready for concrete placement.

In years past, concrete parking lots would be poured using non-productive hand tools and truss screeds. While commercial concrete paving equipment has been on the market for over ten years, it is not until recently that technological advances in the form of 3D Laser Screeds have allowed it to be productively used on parking lots. 3D Laser Screeds allow for concrete to be placed quickly, accurately and at precise elevations to ensure proper drainage and construction. Upon completion of the UltraLot® Whitetopping, early-entry saws are utilized to cut control joints in a tight, controlled spacing pattern. By cutting joints in this configuration we provide the necessary flexibility in the completed surface for proper expansion and optimal pavement life over time. These advances in technology, combined with rising asphalt prices have made concrete paving and whitetopping a great option for parking lots.

For the first time, newly constructed concrete parking lots and whitetopping of existing lots are competing with new or overlayed asphalt parking lots. The real savings and value for concrete paving and whitetopping begins after the work is completed. The average lifecycle for a properly constructed asphalt parking lot is 12 to 16 years with normal annual parking lot maintenance. The average lifecycle for a newly constructed concrete parking lot is 30 to 50 years and a whitetopped concrete parking lot is 25 to 35 years. That is an average lifecycle increase of over 100%, not considering the reduced cost of maintenance overtime (no seal coating required) compared to a typical asphalt parking lot. Now that concrete and asphalt parking lot construction are comparably priced, serious consideration is being given to concrete options for any new parking lot construction or resurfacing project.

Engineers and architects very seldom design parking lots with concrete options for new construction and even less often for reconstruction and overlays. Make a practice of asking for concrete options when building or repaving a parking lot. If you struggle to get clear specifications feel free to call me, Gary Rabine, on my cell phone at (815) 693-9706. In the battle between concrete and asphalt, we only care that the customer wins.

by Webmaster | Feb 27, 2014 | News

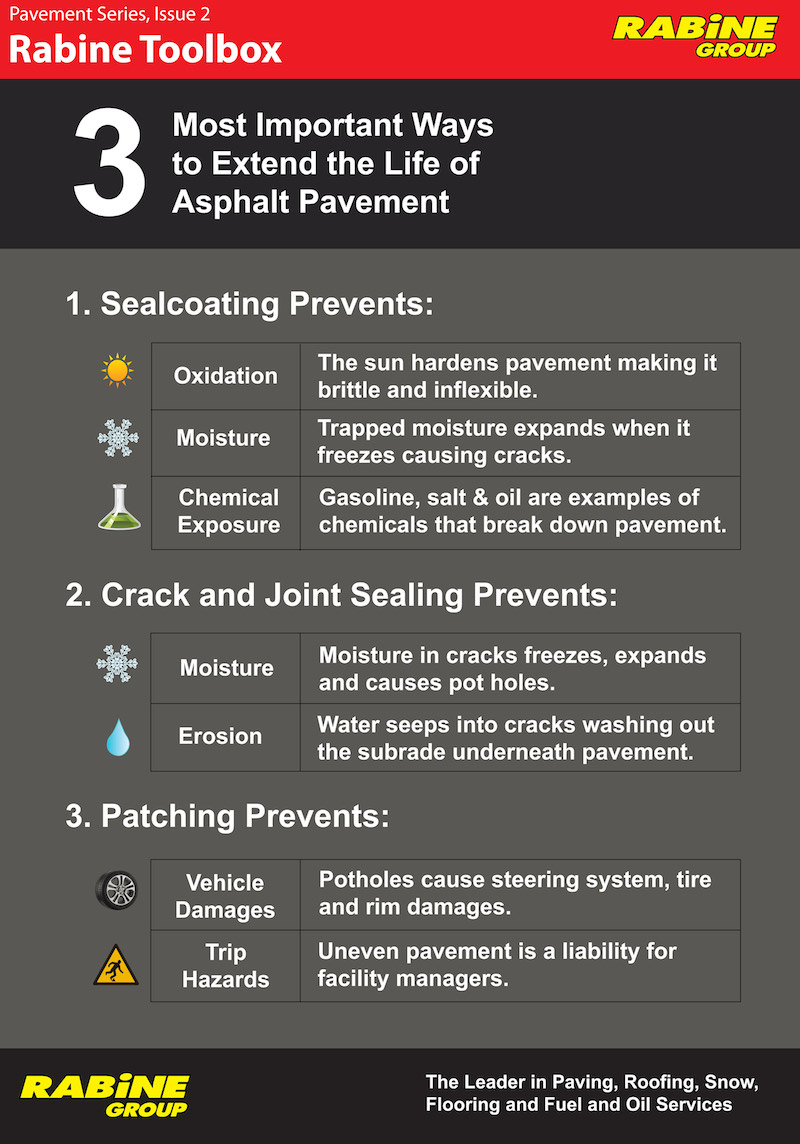

Maintenance is key to extending the life of any pavement. External forces such as weather and traffic can take there toll on your pavement—but there are steps you can take to avoid any further deterioration and extend your pavement’s life.

We’ve put together a list of the three most important tips for maintaining a healthy parking lot or driveway. These are basic but vital steps towards keeping your pavement looking clean and pothole free for years to come.

Ready to protect your pavement? Contact a Rabine representative today

by Webmaster | Feb 27, 2014 | News

Replacing asphalt pavements can be an expensive, inconvenient and time-consuming headache for property managers and building owners alike. By utilizing proper pavement maintenance principles, you can double the life of your pavements and save thousands of dollars in the process.

Proper Crack Sealing

The most important component of proper pavement maintenance is crack sealing. Crack sealing prevents the infiltration of water into your pavements and aggregate base. Proper crack sealing is your first line of defense and helps eliminate pot holes and buckling pavements.

Crack sealing preparations start with the existing cracks being routed to a consistent width and depth of 1/2” by 1/2”. The routing forms a reservoir or a saddle for the sealant to bond in. The heat of the router cutters also seals shut the bottom of the crack and eliminates the possibility of the hot sealant running into the aggregate base. Rabine Pavement Solutions feels so strongly about the positives of routing that we do not offer non routed crack sealing in our service lines.

High-pressure compressed air is then used to completely clean the reservoir of dirt and debris. In the event that the reservoir is damp, a heat lance should be used to dry the area to insure the proper bonding of the sealant. The hot rubberized sealant is then injected in the reservoir and struck off with a squeegee. The finished material should dry approximately 3/8” below the existing asphalt to insure that the material isn’t hooked by a plow or heavy vehicle.

Routed crack fill that is still in the reservoir can do its job after 8 or 9 years. Non routed or over banded cracks can fail after the first winter and can be a poor investment for the owner. Spend more money up front and demand cracks are repaired properly.

Choosing a Coating

The two most basic and affordable coatings are coal tar and asphalt based emulsions. Commercial based coal tar emulsions have been on the market since the 1950’s and are still regarded as the most durable and cost effective product for sealing asphalt. Coal tar is resistant to water, gas, and chemical infiltration. The negatives for coal tar are a strong creosol odor and the burning of skin if you are around the product for an extended amount of time.

Asphalt base sealers have many of the same qualities as coal tars and dry a very dark, rich black color. The negative for asphalt is that it is hard to place in cooler temperatures and wears a little quicker than conventional coal tars.

Rabine Pavement Solutions has started to shift away from predominately using coal tar sealers. We are finding that some of the hybrid polymer modified asphalt sealers are wearing great and drying super black in color, which accents the striping.

Pavement Markings

There are dozens of paints offered for many different installations. The most common paints used over seal coats are water based or latex based paints. Latex paints are inexpensive, easily applied with airless equipment and easy to clean. The big downside is that the paint dulls soon after placement. Acetone paints on seal coat are solvent-based paints with more pigments and the color stay crisp longer.

Another very versatile paint we like to use on oxidized asphalt or concrete surfaces is chlorinated rubber. This paint is flexible and last a long time. It works great for painting concrete curbs or car stops.

The Proof is in the Pudding

A great customer in northern Illinois who owns a large car dealership and who is a real proponent of asphalt pavement maintenance recognized early on that he had to protect the huge investment he made in his parking lots when he built the dealership. We meet every year to discuss a comprehensive plan to protect and extend the life of his pavements. By following the principles in this article the owner has replaced less than 5% of his 20 year old pavement to date.

Any property manager or building owner can share in the same success by committing to a yearly review of the property and stick to a maintenance plan with a trusted pavement maintenance partner.

Recent Comments